ProYECTO

¿Por qué GO-GRASS?

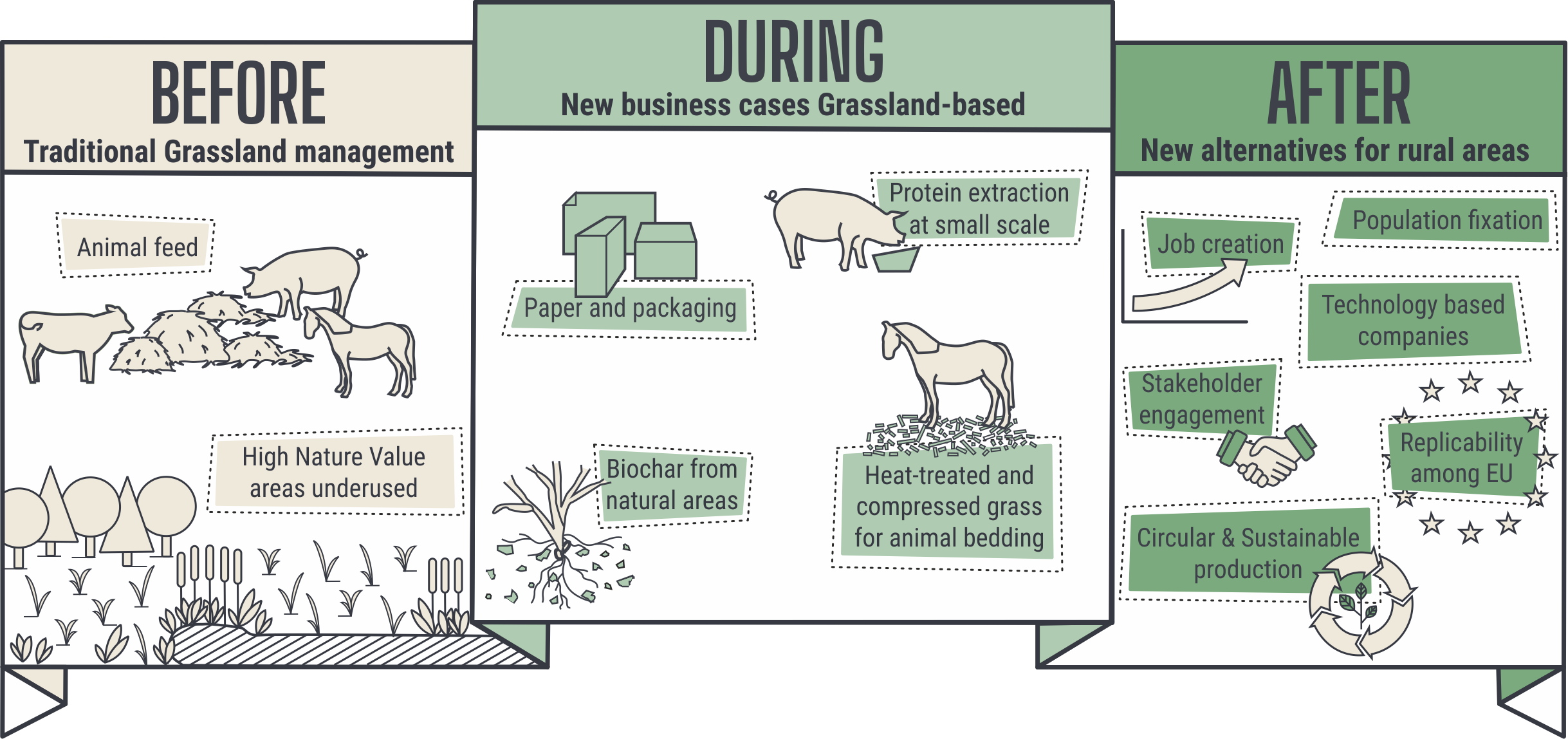

Alrededor del 17% de la superficie total de la UE está cubierta de pastizales y zonas arbustivas. Este recurso está prácticamente inutilizado. Además del potencial desaprovechado, el abandono de estas zonas crea además costes, tanto cada nivel individual como para la sociedad en su conjunto.

GO-GRASS está comprometido a transformar este potencial desaprovechado, volviéndolo útil, reduciendo la importación de nutrientes y la dependencia de los combustibles fósiles y buscando nuevas formas de transferir los beneficios obtenidos para reforzar las comunidades rurales.

Nuestros Objetivos

Since October 2019, GO-GRASS is developing sustainable circular business models considering social, economic and environmental impacts in rural areas.

By harnessing regional assets, GO-GRASS aims to diversify and revitalise rural economies and provide quality jobs and opportunities in co-operation with entrepreneurs and local authorities.

Making grass a raw material for industrial processing offers farmers opportunities for organising new business models. GO-GRASS results show that farmers could work together in cooperatives to supply grass for processing, or that pre-treatment of the biomass could be undertaken by the farmers.

Farmers could install equipment for processing grass for e.g., animal bedding or biochar at farm-scale and work to develop a distribution network beyond the local area.

The project targets large-scale replication especially in remote communities with unexploited resources.

The GO-GRASS consortium consists of a multidisciplinary team of 22 partners from eight European countries (Germany, Spain, Denmark, Sweden, The Netherlands, Belgium, Romania and Hungary).

The project is built around four promising regional demonstration sites located in The Netherlands, Sweden, Germany and Denmark. At these demonstration sites, partners collaborate with farmers, research centres and local technological companies to create grass-based products.

The four Demos have proven that the value chains for processing grass into protein powder, animal bedding, fibres for paper making, and biochar can be established and offer market-ready products. Optimisation of the technologies for grass processing and market creation are fundamental requirements for establishing the grass-based value chains.

The economic feasibility of the value chains depends on the valorisation of side streams. Technologies for processing of side streams are available but a full valorisation of all side streams is often hampered by the lack of access to biogas grids, drying facilities or scale.

Logistics is a key to feasibility of grass-based value chains. Transportation of biomass for processing must be reduced to a minimum to keep costs down and preserve biomass quality.

Due to seasonality issues, it is important to consider handling and storage of the biomass in collaboration with public sector installations like compost facilities, or by farmers for storing e.g., baled dry grass.

Three follower partners from Hungary, Romania and Spain, are taking part in the project to determine if the solutions tested on the four demonstration sites can be be replicated in their regions.

The replication workshops were welcomed with great interest and different actors of the value chain jointly discussed the replication opportunities according to local conditions and needs. For example, in Hungary grassland farmers were interested in how they could make use of the surplus grass, and biochar producers were curious about other possible solutions and technological practices for developing their products.

4 pilotos DE DEMOSTRACIÓN

Para desarrollar modelos de negocio rentables y circulares que exploten el potencial infrautilizado de los recursos de pastos, los socios de GO-GRASS ensayan una amplia gama de soluciones en cuatro prometedores pilotos regionales de demostración situados en Países Bajos, Suecia, Alemania y Dinamarca.

Camas para ganado

en Suecia

Biochar

en Alemania

Papel y embalajes

en los Países Bajos

Proteína orgánica

en Dinamarca