The Green Gold: Biorefining Grass into Animal Feed

When Associate Professor Morten Ambye-Jensen thinks of grass, he thinks of a nice smell and a lot of work. Since 2014, the scientist from Aarhus University has been developing and optimising the biorefining of grass, a technology to separate grass protein and fiber. Ambye-Jensen sees a huge potential in grass. It can be used not only to produce biogas, but also as biomaterials and its protein as a soy alternative in animal feed. In front of their operation plant, where he leads all biorefinery tests for the GO-GRASS project, he speaks about the potential of grass biorefining for agriculture and beyond. – The following interview has been edited and condensed.

© Lars Kruse, Aarhus University Foto

How come we start using grass with biorefining just now?

The technology of getting protein out of grass is not new at all. It has been known since before the 20th century. After World War II, it has been seriously looked at extracting protein from green leaves to feed people that were suffering from malnutrition.

How does biorefinery of grass work?

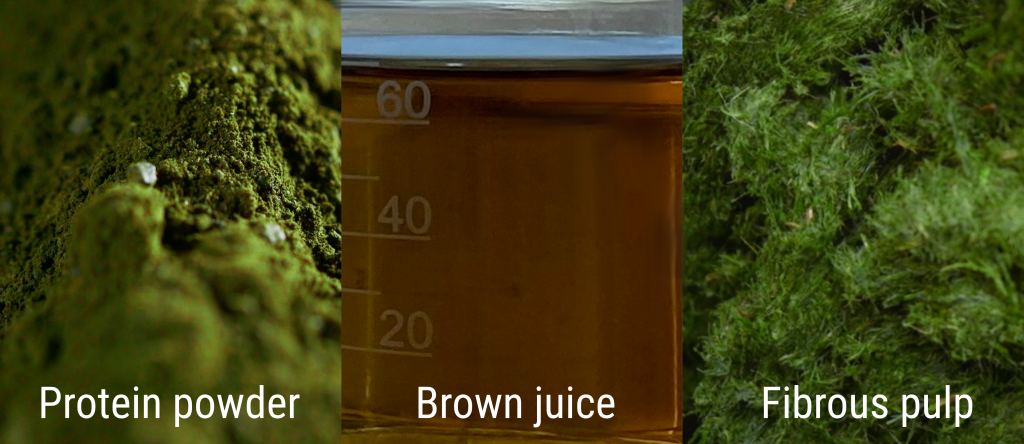

Biorefining is analog to oil refining, but we use biomass and process it into sustainable, marketable products. Here at the platform, we receive freshly harvested grass, clover or green leaves. We macerate and press the fresh grass into a green juice and a fibrous pulp fraction. The green juice contains about half of the protein from the grass. Then we separate the protein from the juice. So, we heat the juice up to 85 degrees and then we centrifuge it. We get a solid fraction, which is the protein concentrate, and a liquid called brown juice, which contains soluble sugars and nutrients.

© ESCI (left & right) and Morten Ambye-Jensen (middle)

What can you use the protein concentrate for?

We use the protein concentrate for feed, to substitute the soy used in the feeding of monogastrics like pigs and poultry. We tested the product in actual feeding experiments. What we have seen is that, we can substitute 100 percent of the soy in pig feed without any negative effect on growth or meat quality.

Pork production is a big sector and would require large amounts of grass protein. How much protein can you extract from the grass?

In fact, we in Denmark would need approximately half a million to one million hectare of grass to substitute our soy protein import of around one million ton. The plant is designed for processing approximately 10 tons of fresh grass per hour, which is around 2 tons of dried grass. The protein concentrate that we get out is approximately 10 percent of the dry weight input. But we are working a lot on the optimisation of the process in terms of yield.

What measures do you take to optimise the yield?

At Aarhus University we worked on the green biorefining development for seven years. It has been a long way, you can say, and a lot of tests and process configurations. For example, we have made a test where we look at different harvesting techniques, comparing fine cutting the grass in the field to harvesting it whole and bringing it to the biorefinery. We are very interested in finding out what is the time window that we can operate in between harvest and processing of the grass. The potential risk is the loss of the protein or reduction of its quality during storage because of biological processes. This is very important for logistics when we think about scale-up of this technology and its implementation into agriculture. Also, we work on extracting more protein from the green juice and the fiber press cake. This is mainly an optimisation of the physical treatment that we give to the grass before or during the pressing.

Are there other potential applications for grass protein or the other biorefining products, like the fibrous pulp?

The protein concentrate could also be used for food and the fibrous pulp can be used for ruminant feed or biomaterials. 70 percent of the grass that we put in comes out as fibrous pulp. So, it is very important that there is a market for this product. It is definitely possible to use it as a good feed for ruminants. What is happening is that we are mechanically treating the fiber, which may open up the structure and the ruminant can utilise the nutrients in the fiber much better compared to the original grass. We are also looking at using the fiber pulp for biomaterials. This includes packaging, bio textiles or paper.

Is there a market potential for the liquid product from grass biorefinery, the brown juice?

In the brown juice, we have organic compounds and inorganic nutrients. The brown juice can be used as a substrate for fermentation processes or simply as fertiliser.

At the moment, we are looking very much into membrane filtration to separate and concentrate different compounds from the brown juice. The process is similar to what the dairy industry is doing to the whey, which used to be a waste product but is now a million dollar product.

So, biorefined grass products offer a whole palette of possibilities.

Green biorefining has a huge potential for the future, for agriculture; also globally. There is a lot of green biomasses out there that could be processed in similar ways. But it is very important that we get the technologies out into agriculture and industry, so that the optimisation and the development is much faster. In Denmark we have two commercial pilots in operation since 2021. Both sites collaborate closely with the demonstration platform of Aarhus University. This will speed up the development for economically robust business cases to utilise grasses and legumes.